Enabling Thermoplastic Encapsulated Designs

Expert Thermoplastic Encapsulation & Overmolding

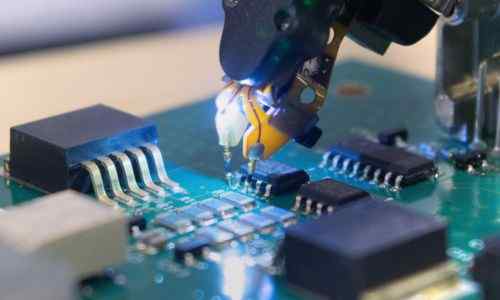

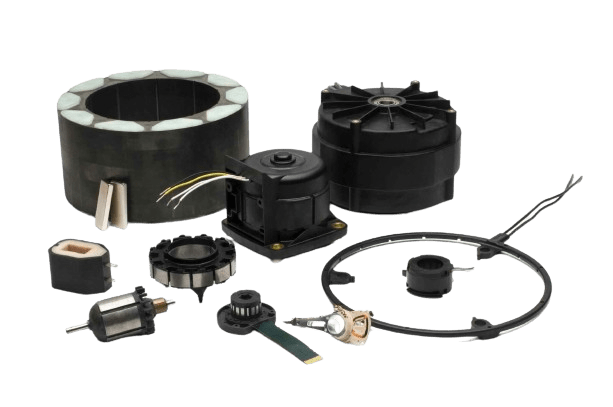

At Encap Technologies, we provide thermoplastic encapsulation solutions that enhance your system’s cost, performance, and longevity. Our intense focus on overmolding of motors and coil wound devices has created specialized knowledge, expertise, and innovation, all of which can be leveraged in your situation. We enable high yield rates when overmolding costly electromechanical components. Areas of specialty include wound stator overmolding, molded ground insulation, rotor magnet fixing, stator segments, “loose” laminations, and encapsulation of coil wound devices.

Since 1998, Encap Technologies pioneered many applications now seen around the world. We can help you simplify current assemblies, cut costs and manufacturing cycle times, reduce thermal rise, improve performance, and gain a competitive advantage. We can help you imagine, design, and prototype, and then provide contract manufacturing or set up a production cell in your facility. Choose Encap Technologies for exceptional encapsulation services and dedicated support.

Our Services

Product Development

- Electromagnetic and thermal design expertise

- Pre-existing tools reduce time and cost

- Extensive experience fabricating subcomponents and custom wire winding

- Wire Guardian® process control reduces the number of inserts required for process development

- Prototype tooling can be designed to produce hundreds of thousands of parts where requried

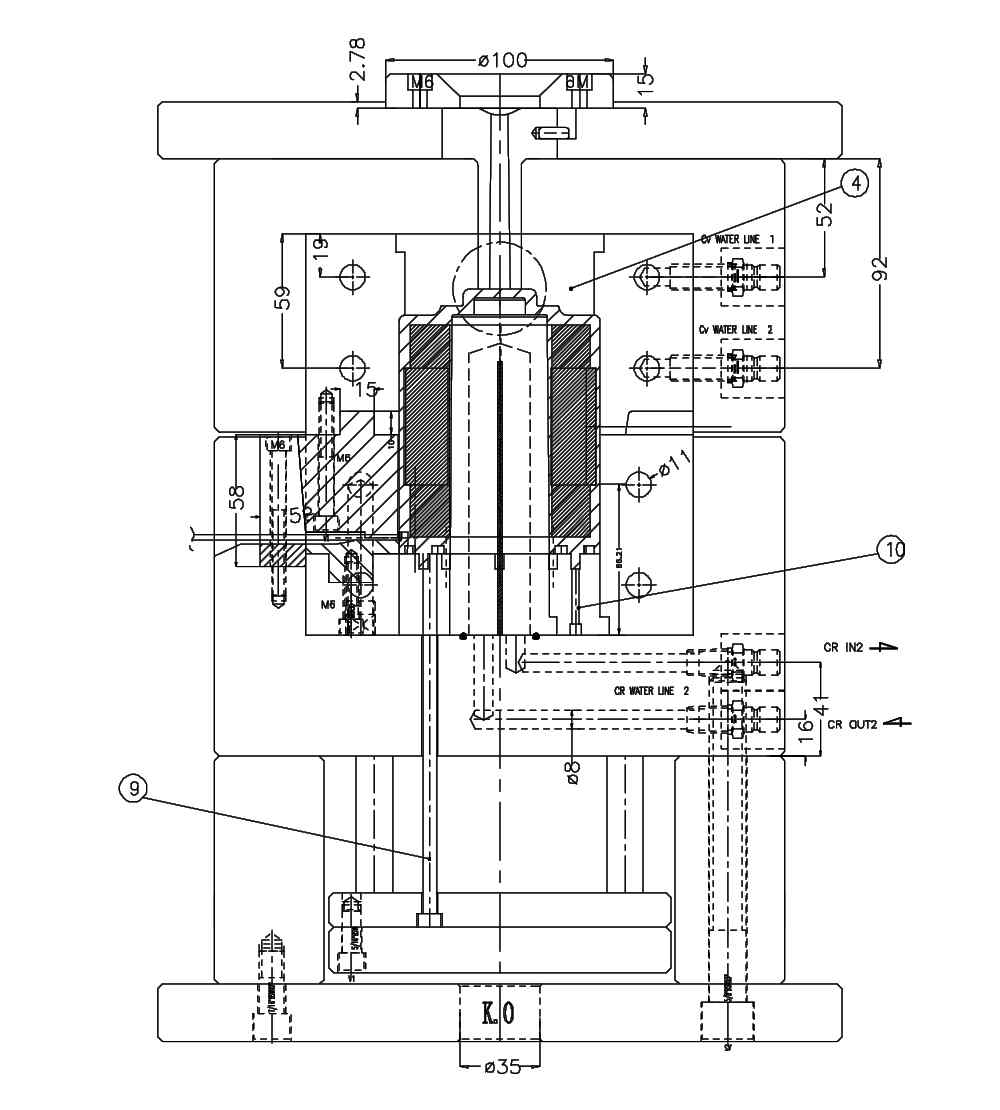

Toolmaking

- Modular molds can produce multiple stack lengths

- Interchangeable inserts are used to create multiple frame sizes and external geometries

- Lead wires, terminals, rigid or flexible circuit boards can be accommodated

- Threaded inserts, bushings, and heat sinks can be product options

Contract Manufacturing

- Lamination fabrication

- Wire Winding

- Sub-component acquisition

- Molding capabilities from 5 gram to 10 Kg

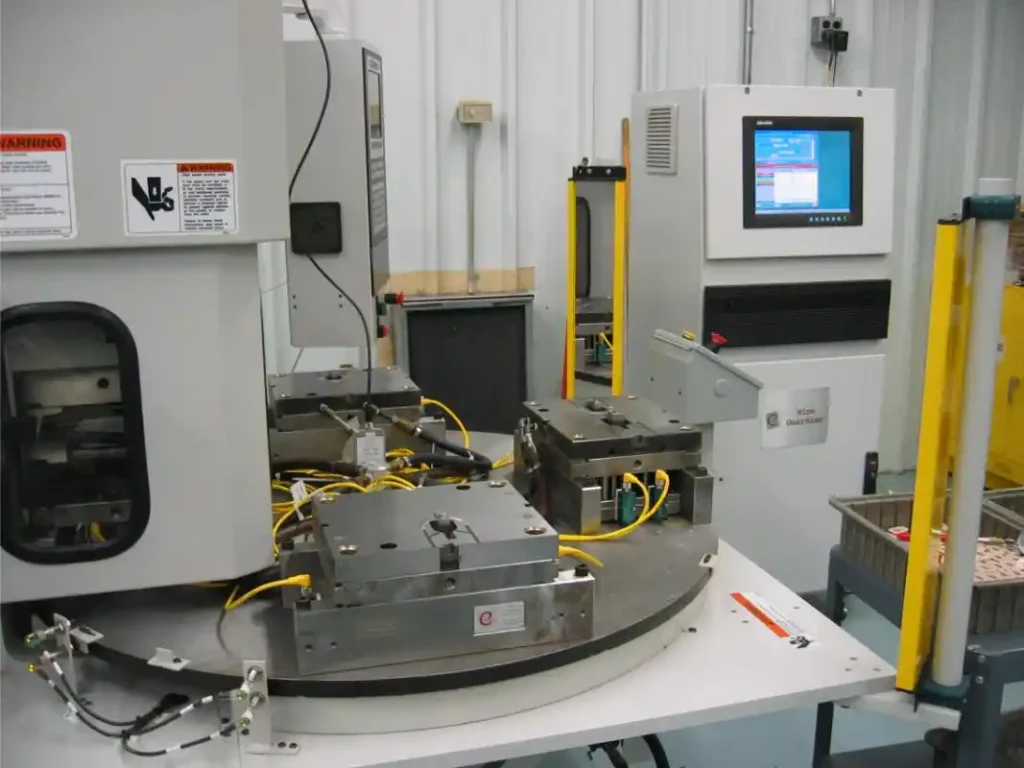

Production Cell Installation

- Installed in customers factory

- Proprietary Wire Guardian® process control customizable for most injection molding machinery

- Online remote process support available 24/7

- Operator training on site and in Encap’s laboratory

Innovative Technology

We utilize cutting-edge technology to deliver efficient and reliable thermoplastic encapsulation solutions.

Quality Assurance

Our rigorous quality control ensures that every product meets the highest industry standards.

Proven Track Record

With a history of successful projects, our proven expertise guarantees reliable and effective encapsulation solutions.

Encapsulation / Overmolding Benefits in Electro-Mechanical Devices

Optimized Cost and Performance

Encap Technologies’ thermoplastic encapsulation reduces costs, eliminates components, and boosts product performance and durability. By integrating components into a single unit, we streamline design, minimize assembly complexity, and improve reliability. There is no curing, leading to fast cycles and lower costs. Pre-approved UL1446 Insulation Systems help speed time to market.

Encapsulation structurally locks components together and provides electrical insulation, while lowering thermal rise and ensuring cooler, more efficient assemblies. This thermal management boosts overall performance and extends assembly lifespan. Overmolding also reduces system costs, vibration, and noise, leading to quieter operation. Encapsulation provides robust protection against environmental factors.

Industry Expertise

We bring years of specialized experience in thermoplastic encapsulation.

Custom Solutions

Tailored encapsulation designs to perfectly meet your specific requirements.

Client Focus

Our commitment is to deliver exceptional results and client satisfaction.